IAEC is Singapore’s first independent vehicle evaluation centre with vehicle scanning technology

Buying a pre-owned car doesn’t have to be a stressful experience. Here’s how to discover your car’s true condition during a pre-purchase inspection.

Buying pre-owned cars can sometimes be a venture into the unknown and even a game of luck, which can be daunting for the inexperienced motorist. A simple walkaround of the car during the viewing in the showroom can be insufficient to uncover problems with your prospective purchase. And while Singapore’s lemon law offers some level of protection, filing claims can be tedious, and often, the buyer runs the risk of not being fully compensated.

The hassle of disputing a regrettable purchase is something no consumer wishes to experience, so what if you could reduce the luck factor and have the actual condition of the vehicle made known to you with full transparency?

A pre-purchase inspection (PPI) allows consumers to assess the actual condition of their potential purchase before committing to a deal.

While a PPI is paramount to understanding the true condition of a prospective vehicle, traditional visual checks often fall short and there are still areas that can be improved upon for a fully comprehensive report on the vehicle’s condition.

As it stands, exterior checks are usually done visually or with a paint-thickness gauge at best. However, even with a paint-thickness gauge, one needs to know where specifically on the vehicle to take measurements from. Exterior checks with the gauge are, therefore, largely guesswork and unreliable.

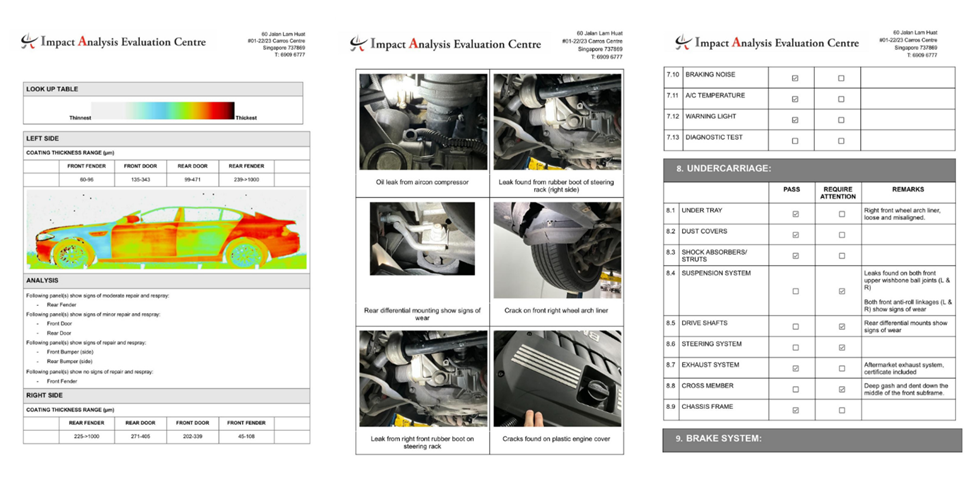

That's where the Impact Analysis Evaluation Centre (IAEC) comes in. Complementing the usual undercarriage and mechanical checks is an advanced vehicle scanner that is contactless and non-destructive to the vehicle’s bodywork. It is able to identify concealed body repairs that are otherwise undetectable by the naked eye, offering consumers a clearer picture of the car’s condition and greater peace of mind regarding their purchase decision.

IAEC’s vehicle scanning technology uses infrared imaging and heat stimulation to scan the exterior body panels to detect any hidden damages, presence of new or refurbished panels, repairs and resprays, and cut and weld jobs.

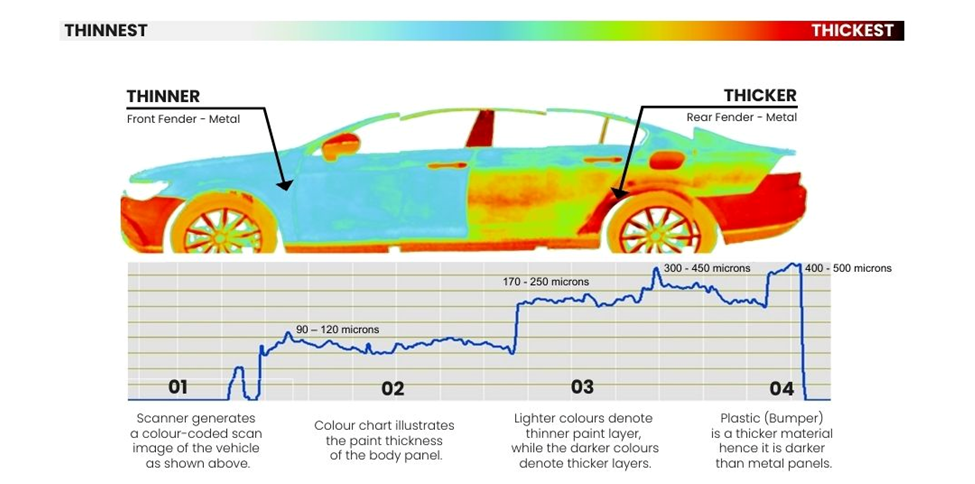

The scanner generates a colour-coded scan image of the vehicle as shown above. The colour chart illustrates the paint thickness of the body panel. Lighter colours denote thinner paint layers while darker colours represent thicker layers. Plastic parts like the bumper are a thicker material and therefore appear darker than metal panels.

After the evaluation is completed, you will receive a full report with all findings clearly explained, showing exactly what may still need attention, as well as what has been repaired, replaced, or resprayed, thereby eliminating any guesswork.

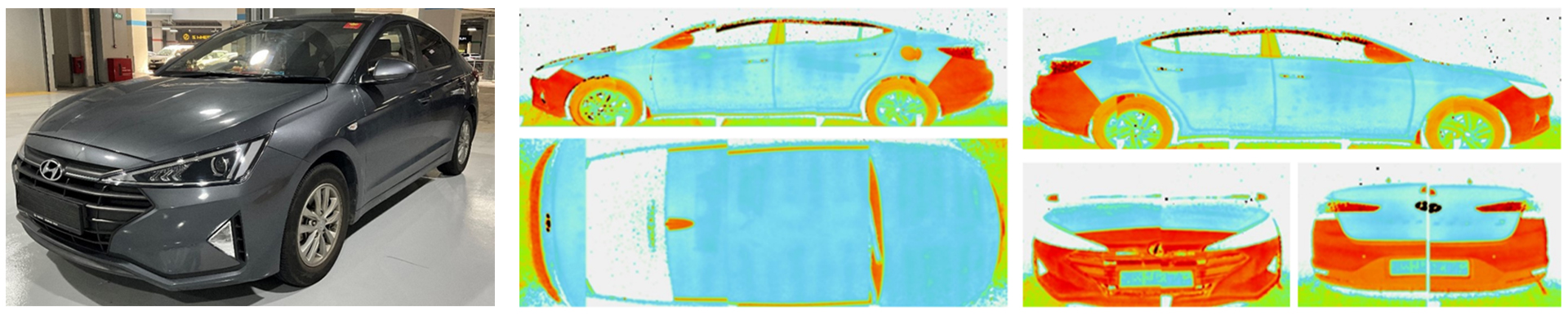

Case Study #1

The car pictured above is untouched and in its original condition and the scan shows homogeneous results throughout. This indicates no signs of repair or respray on any panels.

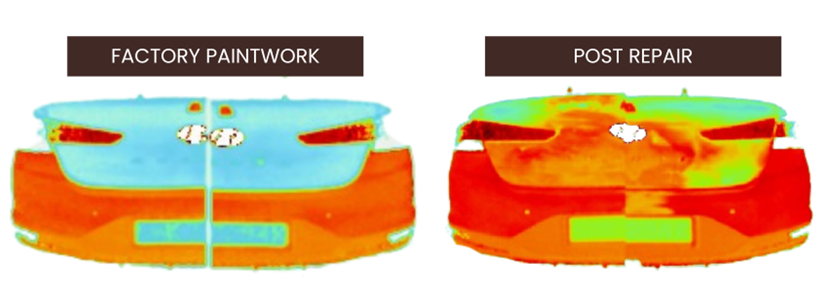

Case Study #2

The car mentioned in Case Study #1 was then involved in an accident.

Top: Photos taken before the repair show damage to the boot lid and rear bumper.

Top: Photos taken before the repair show damage to the boot lid and rear bumper.

Bottom: Photos taken after the repair show the boot lid and bumper fully restored, with no visible signs of the previous damage.

From the photos above, it is nearly impossible to tell with the naked eye whether the affected panels were replaced or repaired – which is where IAEC's scanner comes in.

In comparison to the scan image in Case Study #1, the post-repair scan shows that the colours on the panels are no longer homogeneous across the affected areas.

In comparison to the scan image in Case Study #1, the post-repair scan shows that the colours on the panels are no longer homogeneous across the affected areas.

The scan shows inhomogeneous results on the affected areas (rear bumper & boot lid), which points to both panels being repaired rather than replaced.

Case Study #3

Most passenger cars in production today employ a unibody construction, where the car’s body shell is part of the chassis. Extensive repairs on the body may hide structural damage and improper repairs that could compromise the structural integrity and safety of the car.

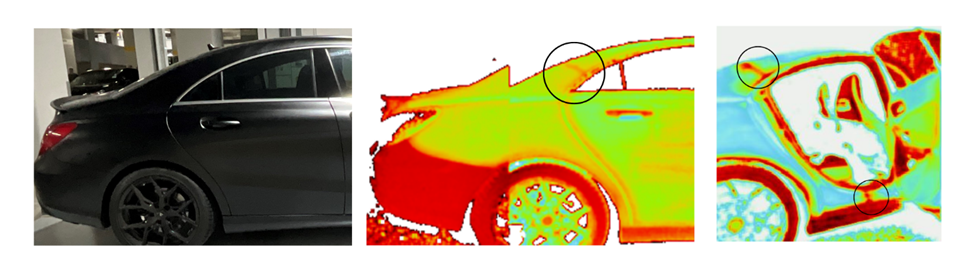

Left: No visible signs of anomalies spotted.

Left: No visible signs of anomalies spotted.

Middle: Scan results revealed a join-line across the C-pillar (marked with circle).

Right: A deeper scan revealed a second join-line, affirming that the car's rear fender has been cut (marked with circle).

In the scenario pictured above, the scanner picked up an irregular join line on the car’s right rear C-pillar, and further inspection revealed a second join line on the sill. That section has clearly been cut with a new panel welded on to repair it. The join lines (marked with circles) are invisible to the naked eye.

The end user is not the only beneficiary. Dealers, parallel importers, and exporters can also benefit from IAEC’s vehicle evaluation services. Whether it’s assessing vehicles before purchase or adding credibility, IAEC helps deliver greater value at every stage of the vehicle sourcing and sales process.

IAEC believes in equipping consumers with the knowledge required to secure good deals and have a fuss-free motoring experience. They aim to achieve that through thorough inspection methods, the use of innovative technology, and objective reporting.

For more information on IAEC and their PPI services, visit https://iaevaluationsg.com/ or contact IAEC at +65 8768 4247 to make a booking.

Super App for

Vehicle Owners

Download the Motorist App now. Designed by drivers for drivers, this all-in-one app lets you receive the latest traffic updates, gives you access to live traffic cameras, and helps you manage LTA and vehicle matters.

Did you know we have a Motorist Telegram Channel? Created exclusively for drivers and car owners in Singapore, you can get instant info about our latest promotions, articles, tips & hacks, or simply chat with the Motorist Team and fellow drivers.